Hope is not a logistics strategy. Expect the unexpected.

Independent expert in European logistics, warehousing and distribution • 22 maart 2020

Keep your goods flowing at all times and under all circumstances

Hope is not a logistics strategy. The current global crisis because of the Corona virus (COVID-19) shows how important it is, for humanity and any business, to keep the flow of (critical) goods moving at all times and under all circumstances.

From my perspective the current crisis will result in structural changes in logistics, transportation and supply chain industries and strategies. Below my first thoughts. I know it's not complete. So please feel free to add any expected changes from your perspective or practical experience. Your contribution will help logistics and supply chain professionals across the globe to develop, implement and execute new logistics or supply chain strategies whenever the next (global) crisis pops up. We need to prepare for "expecting the unexpected". And "prepare for the worst and hope for the best".

Never put your eggs in one basket from a sourcing perspective

Sourcing products from just one supplier or a single country is not a smart thing to do. The COVID-19 crisis and increasing import duties because of "trade wars" are practical evidence for this statement. To my opinion many businesses will review and change their manufacturing & sourcing strategies.

Safety stock and inventory become King again

During the last years many industries have been focussing on reducing stock levels and inventories to the bare minimum mainly because of financial or risk management reasons. But if there's, for whatever reason, no supply possible and demand is still there, or even increases, then one needs to have sufficient stock and inventory. Last year I have been working for a global medical wholesaler and distributor. With safety stock levels for most medical supplies upto 120 days. Honestly, it did surprise me then but with todays Corona knowledge in mind I'm really glad they did. They "expected the unexpected" from a supply chain perspective. I truly believe many business will reconsider their stock and inventory strategies.

National and regional distribution centers will become popular again

Over the last decades many international business have closed national or regional distribution centers and installed central distribution centers: a single warehouse from which customers orders are being picked, packed and shipped out for delivery to the final customer across multiple countries or international regions. An example is an European distribution center which serves customers across the EU or even the entire EMEA (Europe, Middle East and Africa) region. If products can no longer be picked, packed, shipped or delivered from the single central warehouse, your business will stop. Think about disasters like fire, strikes, pandemics, lockdowns etc. In those cases one will need additional distribution centers in (main) markets. Also, E-commerce developments pushes shippers to shorten delivery times and to be closer to their B2B and B2C customers. This development and disaster risk management will thus force shippers to switch to a multi-market distribution center strategy. It might not be cheaper but what will the costs/consequences be once "all hell does break loose" sooner or later?

Logistics cloud software (and internet) are your lifeline

Also in The Netherlands people were told to stay and work from home. But some were no longer able to be productive from home. No VPN or cloud based access to crucial IT business applications like Warehouse Management Systems (WMS), Transportation Management Systems (TMS), Order Management Systems (OMS) or other work related basic IT applications like Email or acces to internal servers, directories and files. Also, this puts your business at risk. ake sure your employees can work from home, at all times and under all circumstances. Expect the unexpected. There are many cloud-based logistics applications out there that will cover your needs and will meet, or even exceed, your expectations.

Warehouse robotics and autonomous trucks developments will accelerate

We humans are vulnerable and we can become sick. In huge numbers, at the same time across the whole globe. We have to make sure the flow of "critical" goods like food and medical supplies is being secured at all times and under all circumstances. Because of this we, humans, will need to become, for our own sake, less dependent on humans across the entire supply chain. To my believe this will also speed up the current developments and investments into AI, robots for warehousing activities and autonomous trucks (trucks without human drivers).

Global supply chain command centers

Multinationals and large companies have production, warehousing, sales, procurement and distribution activities and facilities across the globe. In order to respond quickly, efficient and effectively to disasters and related implications on their supply chains, they will need to have central overview on decentralized supply chain activities to be able to make the best decisions from a global perspective. An example: a specific product might run out of stock in Europe but is still available in large quantities in a North American warehouse. Or last night there has been a fire in a production plant in China but there's still production capacity available in Vietnam (or product can quickly be sourced from a 3rd party supplier in another country). Someone needs to monitor the developments and realted risks and implications from a supply chain perspective. That's why I think there will definitely be (more) "global supply chain command centers" .

Multi modal carrier strategies

Also here, never put your eggs in one basket. In Europe, truck drivers got sick and various governments implemented border crossings checks (resulting in delays in delivery times) once the COVID-19 threat got everybody's attention. But the intermodal and shortsea alternatives kept on rolling. For example, many goods between Italy<->Netherlands, Belgium and Germany have been transported by rail: this eliminates the need of having truck drivers on the train, saves fuel and roadtax and transit times are pretty fast and reliable. Similar intermodal and shortsea alternatives are available for other "long distance" countries like Spain, Portugal, Poland, Eastern Europe, Scandinavia, Ireland and the UK. A multi modal carrier strategy (road, rail, air, ocean, shortsea) will increase the chance your goods keep moving. Even in unexpected times like this.

Look forward to your appreciated comments, thoughts and add-ons. Let's make sure we learn from this pandemic and are (even) better prepared for the next one from a logistics perspective. That's our duty to human mankind: survive, learn and improve.

Last but not least my thoughts and prayers are with all of those who are - or have been - affected by this horrible virus. Also a very special thanks to each and every individual who currently puts his/hers life at risk in helping others to survive and stay alive.

Annual FTL and LTL freight tenders are nowadays very popular at international and European shippers. But to my believe and practical experience plain "spreadsheet or digital freight tendering" is a "race to the bottom" for both shippers and their carriers. Why? Because focus is mainly, or even only, on the cheapest FTL or LTL rate and less on the value a reliable and innovative carrier brings to your daily business and commercial operations. Price is what you pay, value is what you get. And value still does cost money, so your carrier needs a reasonable profit too. There is a way for shippers to massively reduce their logistics and freight spend whilst keeping their carriers and customers happy at the same time. And it's for free.... When talking to international shippers about reducing their European freight and logistics spend, I ask a lot of (detailed) questions with the goal to "discover" and "identify" their logistics savings and improvement potential. And it always surprises me that there's already lots of "money on the table" without them even knowing or realizing it. In those cases, I try to change their mindset from external (carrier rates) to internal improvements. This include but are not limited to freight costs reducing items like: Optimize your product packaging Many products and product packaging are (still) being designed without taking dimensions and weights into mind from a logistics - freight and storage - perspective. A difference of a few inches or kilograms can save shippers lots of money in transportation (road, rail, air, ocean) and storage costs. Space is money! Maximize your pallet configuration Pallets are often not filled to what's possible from a transportation perspective. In Europe the most common pallets are euro pallets (80 x 120 cm) and block pallets (100 x 120 cm). Most European trailers and trucks have an internal height of 250 to 300 cm and a capacity of 33-euro pallets or 26 block pallets. So, maximize your pallet height: getting more products on 1 pallet is less transportation costs per product item. If you also use ocean freight, please be aware that ocean containers have different internal dimensions. Maximize full truck load utilization Also, when it comes down to full truck loads, trucks are often not filled to the max. In many cases there's still a lot of "air" available in the trailer. Due to an inefficient product packaging or improper pallet configuration (as mentioned previously). If there's air, ask yourself why there's air available in the trailer. In Europe, most trailers can carry appr, 23 to 25 tons of product and appr. 80 to 120 m3 (depending on equipment type and transportation mode). A truck with a "double loading floor" system reduces the number of required trucks by 50% as this enables you to make "non-stackable pallets stackable". And at the same time, it significantly improves your carbon footprint. Use the most suitable transportation equipment In Europe there a lots of different equipment types with various internal dimensions and weights. If you ship high volume/low weight products a so-called volume trailer (100 m3) or road train (120 m3) would be most suitable as a 13.60-meter standard trailer can "only" load 80 m3. Another interesting alternative is a pallet wide '45 container for long distance intra-European (intermodal or shortsea) transportation. Choose the best transportation methods Road transport is still dominant in Europe but can be expensive on long distance routes involving road tax, ferries and lots of fuel consumption. Intermodal and shortsea shipping are reliable and cost reducing alternatives on countries like Italy, Spain, UK, Ireland, Eastern European and Scandinavian countries. Dedicated fleet solutions Large shippers with high volumes and daily frequent shipping volumes should consider implementing so-called "dedicated fleet" solutions instead of contracting carriers on a shipment basis. In such a solution the carrier runs - on behalf of the shipper - a dedicated number of trucks - in closed loops or continuous roundtrips - in the shippers’ European distribution network. Dedicated solutions can save shippers millions whilst improving service, reliability and predictability at the same time. A "transportation control tower" concept can have lots of financial and service advantages as well (if there's no conflict of interest). But that's another story to tell. Contract the right carriers for your products and shipping profile Europe holds over 1.000.000 carriers and trucking companies. From small to large. With different service and geographic specialisms. It's a transportation jungle. I'm working already over 30 years in this industry and still adding new carriers every day into my European carrier database. Prior to inviting carriers to submit a proposal you will need to know your shipping profile: products, quantities, shipment size, destinations, weights, dimensions, restrictions, (un)loading times, transit times as well as your and your customer's operational service requirements etc. Based on your shipping profile you will need to select carriers matching your profile. It makes no sense to invite an LTL specialist for FTL. Or a domestic oriented carrier for international part loads. Or a non-TAPA certified carrier for high value transports. Specialists often deliver better service and more competitive prices opposed to generalists. One can't Google experience: ask potential carriers questions to determine their competencies and experience on your specific shipping profile. Ask for company details (number of own trucks and drivers, transportation equipment, transportation modes, specialisms, turnover, number of staff, customer references etc.) prior to inviting them to do a proposal or quotation. Many companies just "Google" some carrier names and send out their quotation request to 10, 20, 30 carriers or even more. To my experience this "quantitative" approach isn't right and just doesn't work. It's better to take your time and develop true partnerships with carriers who have a practical understanding of and proven experience with your products and business. Remember, price is what you pay, value is what you get! How about for free? As owner of "De Transportheker", a 100% independent logistics specialist located in Venlo, The Netherlands, I help international clients to store, move, ship and deliver their products better, faster, easier, greener and cheaper in Europe. This also includes "no cure, no pay" pricing models. In many cases the fees are just a small portion of your total logistics & freight spend savings. In addition, clients are also offered the possibility to hire "De Transportheker" on a project or freelance basis against an attractive manhour rate.

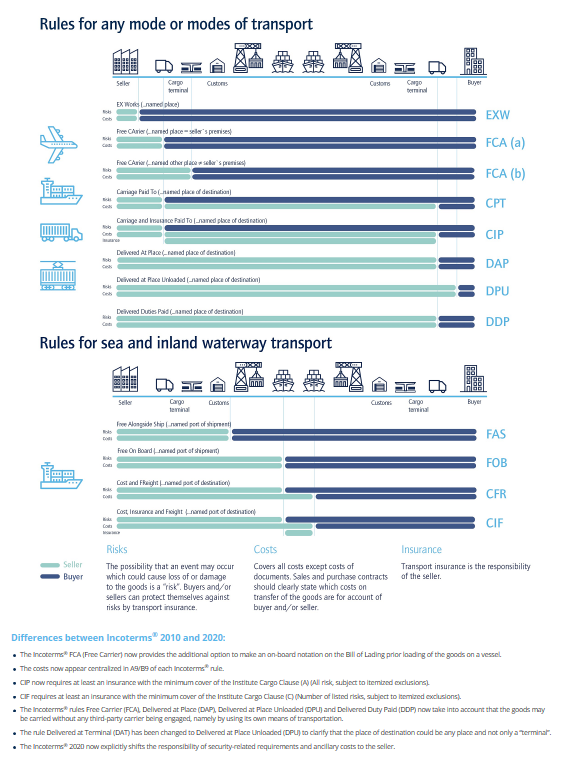

Into international trade? Never forget about incoterms or delivery terms. It can make or break a succesful business transaction. The Incoterms® or delivery term rules are the regulations that define responsibilities and risks of buyers and sellers operating in global trade. They determine how costs responsibilities and risks are allocated to the parties involved. Incoterms rules should be incorporated into #contracts for the sale of goods worldwide and be an integrated negotiation component in your international trade transactions. Source and more info: International Chamber of Commerce